Breaking 50 years of technology monopoly in Europe and America, China successful

2021-09-11

Recently, with the cooperation of Hudong Shipyard and Baosteel and other companies, China has successfully developed Invar, which is as thin as an eggshell, and successfully broke the 50-year technological monopoly of Europe and the United States. The manufacturing of this steel is even more difficult than building an aircraft carrier. What is the main purpose of this material? How to achieve localization?

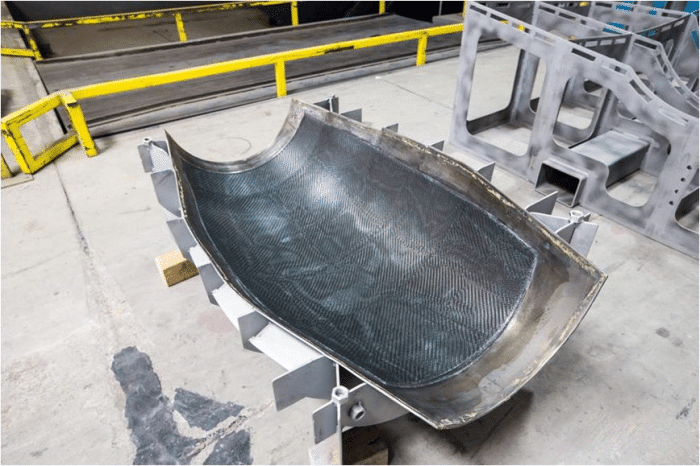

Invar is a metal that is widely used in the industrial field. It will not deform and has a very low expansion coefficient. It is often used in the construction of civil ships. The most common one is the LNG ship that transports liquefied natural gas, because it can maintain low temperature in the ultra-low temperature environment. It is most suitable for deforming and manufacturing equipment containing liquefied natural gas.

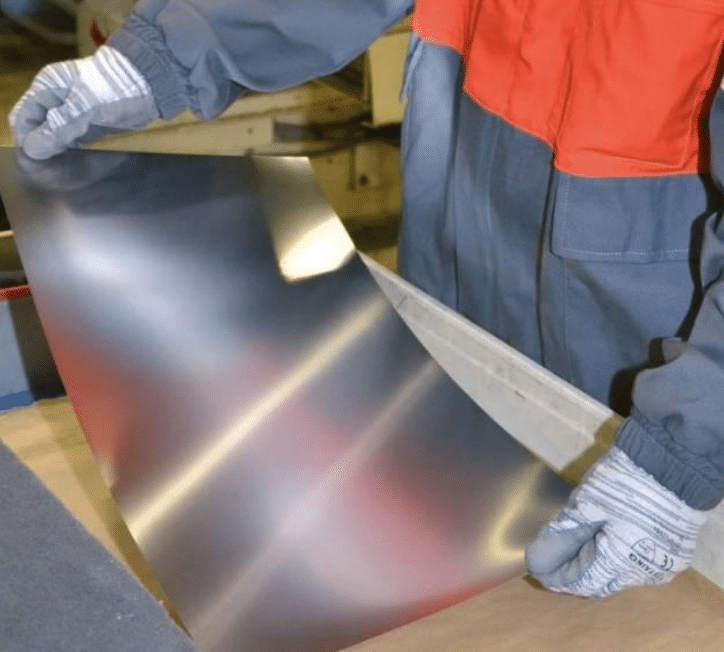

Invar material

Before the breakthrough of Invar production technology, most of them were imported from foreign countries. The price has been high, the procurement cost is high, and it is controlled by others. In order to get rid of this difficulty, Hudong-Zhonghua Shipbuilding Group, together with China Classification Society, Baosteel and other enterprises, invested a lot of manpower and material resources in research and successfully manufactured 0.7 mm Invar.

Invar material

Not only can it be widely used in the shipbuilding industry, but also in the fields of aerospace, laser, optical measurement, and astronomy. For example, such materials are also used in optical measuring instruments. The calibration ruler used in the three-dimensional photogrammetric system is applied to this material, which has good durability. The calibration ruler has high measurement accuracy, and the effect of obtaining three-dimensional data is good. The 3D photogrammetry system uses the calibration ruler to collect data for positioning measurement, and is used with a handheld 3D scanner. For scanning large objects, it can improve the scanning stitching error, thereby improving the scanning data accuracy, and providing customers with an effective solution.

Calibration ruler for 3D photogrammetry system